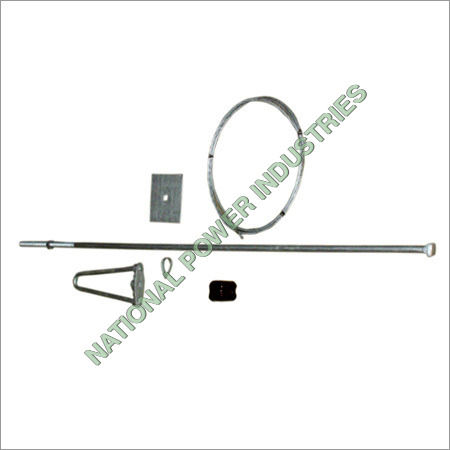

Turn Buckle

Turn Buckle Specification

- Product Type

- Turn Buckle

- Material

- Galvanized Steel

- Capacity

- 500 kg to 10 tonnes, depending on size

- Application

- Tensioning, rigging, lifting, and securing wires, cables, and rods

- Size

- M6 to M36 (custom sizes available)

- Weight

- Varies by size (approx. 200g to 5kg)

- Color

- Silver

About Turn Buckle

We bring forth for our clients a wide assortment of high quality Tum Buckle. This product is well suited for installing wires on towers. Offered product is precisely manufactured by making use of the superior quality raw material under the guidance of our deft professionals in compliance with set industry standards. The complete range of Tum Buckle is appreciated for its rust resistant feature and can be availed from us in various sizes at most affordable rates.

Features:

-

Corrosion resistant

-

Intricate design

-

Sleek finish

-

Thermal shock resistant

Superior Strength and Custom Sizes

Turn buckles come in a variety of standard sizes from M6 to M36, with the flexibility to produce custom sizes for specific project needs. Their robust design ensures safe tensioning and securing, supporting loads from 500 kg up to 10 tonnes, depending on the selected model.

Corrosion-Resistant Galvanized Steel

Made from high-grade galvanized steel, these turn buckles offer exceptional resistance to rust and corrosion. The silver coating not only enhances aesthetic appeal but also increases longevity, making them suitable for outdoor and demanding environments.

FAQs of Turn Buckle:

Q: How are galvanized steel turn buckles typically used in industrial applications?

A: Galvanized steel turn buckles are primarily used for tensioning, rigging, lifting, and securing wires, cables, and rods in construction, marine, and utility industries. Their adjustable design allows precise control of tension and stability in demanding environments.Q: What is the manufacturing process for these turn buckles?

A: The manufacturing process includes cutting and shaping galvanized steel to the required size, threading the ends, and assembling the body and end fittings. Rigorous quality checks ensure each turn buckle meets safety and performance standards before dispatch.Q: Where can these turn buckles be installed or applied?

A: These turn buckles are suitable for both indoor and outdoor settings, including construction sites, shipyards, utility installations, and anywhere secure tension of wires or rods is necessary. Their corrosion resistance makes them ideal for harsh environments.Q: When should I opt for a custom-sized turn buckle?

A: A custom-sized turn buckle is advisable when your project requires specifications outside the standard M6 to M36 range or when a particular load capacity or application needs a unique solution. Customization ensures optimal compatibility and safety.Q: What are the benefits of choosing galvanized steel for turn buckles?

A: Galvanized steel provides enhanced resistance to weathering and corrosion, ensuring longevity even in challenging conditions. This makes the turn buckles reliable for prolonged industrial use and lowers replacement frequency due to wear and rust.Q: How do I select the appropriate turn buckle size for my project?

A: Select the turn buckle size based on the weight and tension requirements of your application. Refer to the capacity range (500 kg to 10 tonnes) and match it to the required load. Consulting with the supplier helps ensure the right fit for your needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transmission Line Materials & Hardwares Category

Stay Wire and ACSR

Price 90 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Color : Silver (Metallic Finish)

Size : 7/8 SWG, 7/3.15mm, 6/1/4.72 mm and customized options

Application : Overhead Transmission and Distribution Lines, Electrical Utility Poles Support

Material : Galvanized Steel, Aluminium

Stay Set With

Price 2000 INR / Set

Minimum Order Quantity : 1 Set

Color : Silver and Black

Size : Standard (customizable)

Application : Pole line fittings, Overhead transmission, Power distribution

Material : High Grade Plastic and Metal

CT Metering Electrical Transformer

Price 150000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Grey

Size : Customized

Application : Industrial

Material : Mild Steel

Moose Conductor

Price 400 INR / Kilograms

Minimum Order Quantity : 4000 Kilograms

Color : Silver

Size : Standard

Application : Industrial

Material : Aluminium

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese