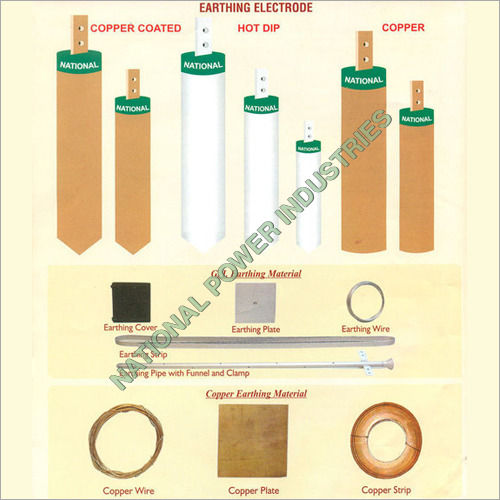

Earthing Electrode

Earthing Electrode Specification

- Mounting Type

- Buried in Ground

- Connector Type

- Copper Strip/Flat Strip

- Surface Finish

- Copper Coated/Polished

- Operating Temperature

- Standard Conditions

- Shape

- Rod/Strip

- Feature

- Corrosion Resistant

- Product Type

- Earthing Electrode

- Application

- Used for providing safe earthing in electrical systems

- Protection Level

- Other

- Color

- Copper/White

- Dimension (L*W*H)

- Varies

- Weight

- Varies

- Warranty

- Standard Manufacturer Warranty

- Size

- Varies

- Connection Type

- Strip/Connector

- Material

- Copper Coated/SS/Hot Dip Galvanized

About Earthing Electrode

Earthing Electrode

Power Grid Switchgear are leading producer of earthing electrodes. Apart from dealing in earthing solutions and lightning protection equipment we also have a remarkable name for our product earthing electrodes. Since Last 40 year Marketed under the brand name of Power Grid Switchgear pvt ltd, these electrodes are acclaimed for features like corrosion resistance, eco-friendliness, excellent efficiency,etc., and are widely used in various application areas such as telecommunication towers and microwave antennas,

Corrosion Resistant & Durable Design

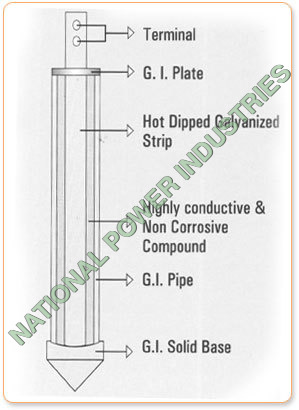

Our earthing electrodes are engineered with advanced corrosion-resistant features, ensuring longevity and consistent performance even in challenging soil conditions. The copper-coated or polished surface finish actively protects the electrode against environmental degradation, resulting in a stable earthing system for years.

Flexible Mounting & Multiple Material Choices

Available in rod and strip shapes, these electrodes offer flexibility in installation and compatibility with a range of connector types, including copper strip and flat strip. Customers can choose materials such as copper-coated steel, stainless steel, and hot dip galvanized steel, catering to distinct site requirements and budget considerations.

FAQs of Earthing Electrode:

Q: How is the earthing electrode installed in the ground?

A: The earthing electrode is mounted by burying it vertically into the ground at a location suited for optimal conductivity. Installation involves connecting the electrode to the electrical system using copper strip or flat strip connectors to ensure a secure and safe earthing link.Q: What materials are used in the construction of these electrodes?

A: The electrodes are constructed from copper-coated, stainless steel (SS), or hot dip galvanized steel, providing robust corrosion resistance and electrical conductivity suitable for various soil and environmental conditions.Q: When should a corrosion-resistant earthing electrode be used?

A: Corrosion-resistant earthing electrodes are recommended in settings where soil moisture and chemical content may accelerate metal degradation. Using these electrodes enhances safety and maintains the reliability of the earthing system over time.Q: Where are these earthing electrodes commonly used?

A: These electrodes are applied in industrial, commercial, and residential buildings throughout India. They are essential components in new electrical installations and upgrades, ensuring proper grounding and protection against electrical faults.Q: What is the process for connecting the electrode to my system?

A: Connection is accomplished using compatible copper strip or flat strip connectors, which provide a secure joint between the electrode and your electrical system. This ensures effective grounding and meets standard safety regulations.Q: How does a copper-coated finish benefit the electrode?

A: A copper-coated finish improves electrical conductivity and protects the metal core from corrosion, extending the life of the electrode and maintaining efficient earthing over prolonged periods.Q: What advantages does standard manufacturer warranty offer?

A: With a standard manufacturer warranty, customers have assurance regarding product quality and support, covering manufacturing defects and giving peace of mind during installation and operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Earthing Material Category

Electrical Earthing Electrode

Price 500 INR / Piece

Minimum Order Quantity : 1 Piece

Protection Level : Other

Application : Used for providing safe earthing in electrical systems

Color : White

Product Type : Electrical Earthing Electrode

Earthing Strip

Price 70 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Protection Level : Other

Application : Used for providing safe earthing in electrical systems

Color : Metallic

Product Type : Earthing Strip & Pipe

Earthing Electrode / Materials

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Protection Level : Other

Application : Used for providing safe earthing in electrical systems

Color : Copper / White

Product Type : Earthing Electrode

GI Earthing Electrode

Price 500 INR / Piece

Minimum Order Quantity : 1 Piece

Protection Level : Other

Application : Used for providing safe earthing in electrical systems

Color : Silver

Product Type : Earthing Electrode

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese