डिसà¥à¤à¤¾à¤°à¥à¤à¤¿à¤à¤ रà¥à¤¡/à¤à¤ªà¤°à¥à¤à¤¿à¤à¤ रà¥à¤¡

डिसà¥à¤à¤¾à¤°à¥à¤à¤¿à¤à¤ रà¥à¤¡/à¤à¤ªà¤°à¥à¤à¤¿à¤à¤ रà¥à¤¡ Specification

- ऑटोमेशन ग्रेड

- Manual

- मॉड्यूल की संख्या

- Single

- फ़िनिश टाइप

- Smooth Insulated

- सर्किट टाइप

- Single Circuit

- सुरक्षा स्तर

- IP 20

- तापमान सीमा

- -10°C to +55°C

- रिस्पांस टाइम

- Instantaneous

- मैकेनिकल लाइफ

- Over 10,000 operations

- रेटेड वोल्टेज

- 33 kV AC

- मैक्स। मौज़ूदा

- 10 kA for short duration discharge

- प्रॉडक्ट टाइप

- Discharging Rod / Operating Rod

- मटेरियल

- High-grade FRP (Fiber Reinforced Plastic)

- इन्सुलेशन प्रतिरोध

- ≥1000 MΩ

- संपर्क प्रतिरोध

- < 50 μΩ

- मैक्स। वोल्टेज

- 33 kV

- परिचालन तापमान

- -10°C to +55°C

- साइज

- Standard lengths (customizable) - typically 6ft, 8ft, 10ft

- रंग

- Red / Yellow

- वज़न

- Approx. 2-3 kg (varies with length)

- माउंटिंग टाइप

- Handheld / Manual

- मौज़ूदा रेटिंग

- 10 kA (Discharge)

- ध्रुवों की संख्या

- Single Pole

- Dielectric Strength

- > 100 kV

- Handle Type

- PVC Insulated Grip for Operator Safety

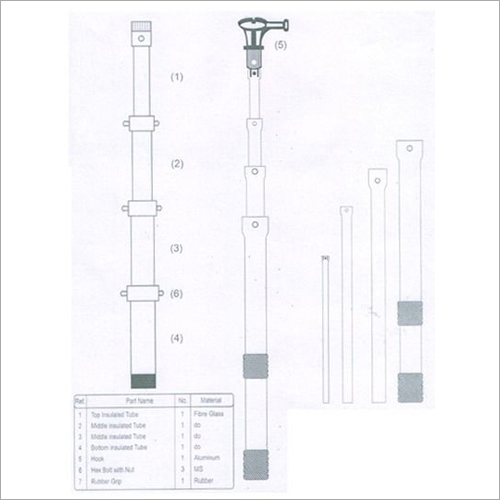

- Rod Sections

- 2 or 3 sectional (collapsible/extendable)

- Applicable Standards

- IS 2071, IEC 60855, ASTM F711

- Test प्रमाणपत्र

- Supplied with Routine and Type Test Reports

- Usage

- Safely discharge residual charge from high voltage equipment

- Hook Material

- Copper alloy with anti-corrosive plating

- End Fittings

- Brass / copper alloy fitting

- Storage Case

- Supplied with robust carrying case

About डिसà¥à¤à¤¾à¤°à¥à¤à¤¿à¤à¤ रà¥à¤¡/à¤à¤ªà¤°à¥à¤à¤¿à¤à¤ रà¥à¤¡

Discharging Rod / Operating Rod

Discharge Rod and Operating Rod are. Available in various specifications of 11 KV/22 KV/ 33 KV, These earthing rods are manufacturer in our plant that is fully automatic and have strong electrical and mechanical strength. It is convenient to handle and easy to work, it is light weight and vibration free. It is 100% safe with guaranteed long life and no maintenance, Discharge Rods is an insulated pole, usually made of fiberglass, used by electric utility workers when engaged on live-line working on energized high-voltage electric power lines.

Operating Rods, offered by us, are designed in various formations, which are proved to be use in Earthing Tree Cutting D O Fuse A B Switch and many applications. Clients can avail Discharge & Operating Rods in required capacity.

Reliable High-Voltage Safety Tool

Designed for swift and secure discharge of residual electric charge from equipment up to 33 kV, this operating rod prioritizes operator protection with advanced insulation and robust FRP construction. Suitable for power utilities, substations, and maintenance teams, its collapsible sections offer ease of transport and storage. Each rod is manufactured to international safety and quality standards, ensuring dependable insulation and durability for high-voltage tasks.

Premium Material and Construction

Our discharging rod features high-grade fiber reinforced plastic (FRP) for light weight and mechanical strength. The copper alloy hook bears an anti-corrosive plating to withstand tough environments. Brass/copper alloy fittings and a smooth insulated finish further enhance its longevity. Designed for handheld operation, the PVC insulated handle guarantees safe usage even under demanding conditions. Every rod is supplied with a storage case and certified test reports for complete peace of mind.

FAQs of Discharging Rod / Operating Rod:

Q: How does the Discharging Rod ensure operator safety?

A: The Discharging Rod safeguards users by incorporating a PVC insulated grip, high dielectric strength (>100 kV), and an insulation resistance of 1000 M. Its robust FRP construction prevents electrical leakage, making it safe for manual discharge procedures.Q: What is the process for using the Discharging Rod to discharge high-voltage equipment?

A: To discharge residual voltage, the operator manually extends the rod, connects the copper alloy hook to the charged part, and ensures firm contact. Instantaneous response and high conductivity protect against sudden surges during discharge. Usage should always follow recommended safety guidelines.Q: When should this rod be used in electrical operations?

A: This rod is essential whenever de-energizing or servicing high-voltage equipment up to 33 kV, especially in substations, maintenance projects, or after switching operations, to safely remove residual electrical charge prior to hands-on work.Q: Where can the Discharging Rod be applied?

A: It is suitable for power utilities, substations, industrial installations, and any setting where high-voltage apparatus (up to 33 kV) requires safe discharge. The supplied carrying case facilitates its transport to various field sites.Q: What standards and certifications validate the quality of the Discharging Rod?

A: The rod is manufactured and tested as per IS 2071, IEC 60855, ASTM F711 standards. Each unit is supplied with routine and type test reports, confirming compliance and quality assurance.Q: What benefits does a collapsible (sectional) rod provide?

A: Collapsible or extendable rod sections allow easy storage, portability, and quick assembly, making the tool practical for field engineers who need efficient mobility without compromising strength or safety.Q: Is customization available for the rods size or length?

A: Yes, standard rod lengths are typically 6ft, 8ft, or 10ft, but custom sizes can be provided as per operational requirements. This ensures optimal reach and safe operation for diverse high-voltage applications.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in Discharging Rod / Operating Rod Category

डिस्चार्जिंग रॉड/ऑपरेटिंग रॉड

मैक्स। वोल्टेज : Up to 33KV

परिचालन तापमान : Standard

इन्सुलेशन प्रतिरोध : High

वज़न : Lightweight

फ़िनिश टाइप : Smooth

तापमान सीमा : 10°C to +55°C

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese